Manufacturing cycle efficiency definition

/What is Manufacturing Cycle Efficiency?

Manufacturing cycle efficiency measures the proportion of production time spent on value-added activities. A business can use this information to pare away non value-added activities, thereby reducing costs and shortening the time required to manufacture a product. Both outcomes can be used as competitive advantages, since a business can then lower its prices while maintaining robust profits, while also offering faster turnaround times to its customers.

How to Calculate Manufacturing Cycle Efficiency

To calculate manufacturing cycle efficiency, divide value-added production time by total cycle time. Total cycle time is the aggregate amount of all process time, inspection time, queue time, and move time. A typical outcome of this analysis is to find that process (value-added) time comprises an inordinately small part of the total cycle time. All remaining parts of total cycle time are non value-added, and so should be examined to see if they can be compressed or eliminated.

Example of Manufacturing Cycle Efficiency

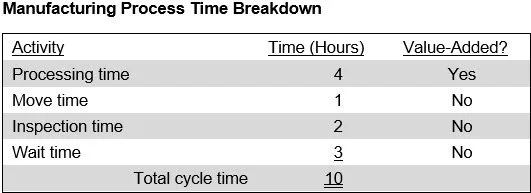

An analyst finds that a particular production process requires the time intervals noted in the following exhibit.

The resulting manufacturing cycle efficiency calculation is:

4 Hours value-added time ÷ 10 Hours total cycle time = 40% Manufacturing cycle efficiency

This means that only 40% of the total manufacturing cycle time is spent on activities that actually add value to the product, highlighting opportunities to improve efficiency by reducing non-value-added time.

Related AccountingTools Courses

FAQs

How does automation affect manufacturing cycle efficiency?

Automation can improve manufacturing cycle efficiency by reducing processing time and minimizing waiting, inspection, and movement. By streamlining workflows, it increases the proportion of value-added time within the total cycle. However, poorly designed automation can introduce new bottlenecks that offset these gains.